categorias

recente Postagens

Para facilitar a dispersão dos pigmentos perolados, você pode pré-umedecê-los.

O tempo de umedecimento deve ser de pelo menos 15 minutos.

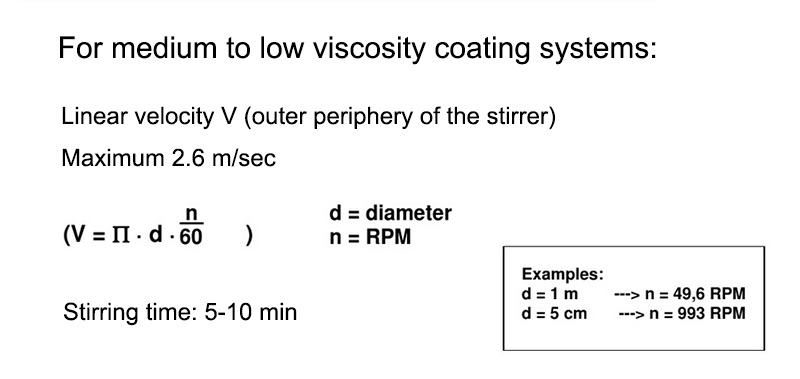

Primeiramente, recomenda-se misturar parte do pó de pérola com um solvente, diluente ou plastificante compatível para formar uma pasta. Em seguida, incorpore a pasta uniformemente à porção restante. Os pigmentos de pérola podem ser dispersos utilizando um agitador comum, semelhante ao utilizado para pós metálicos. O método correto de agitação é o seguinte: adicione o pó de pérola a um veículo que esteja sendo agitado com baixa força de cisalhamento utilizando um misturador axial. O pigmento não deve ser adicionado de uma só vez, mas gradualmente. Continue adicionando conforme a primeira porção for umedecida até que todo o pigmento esteja umedecido. Por fim, continue agitando por 15 minutos para garantir uma melhor dispersão. Um agitador axial rotativo também pode ser utilizado, com o volume de pigmento inferior a 25% e a velocidade de agitação não muito alta.

Durante a agitação, a altura da pá do agitador deve ser variada para evitar uma mistura irregular nas zonas mortas diretamente abaixo da pá.

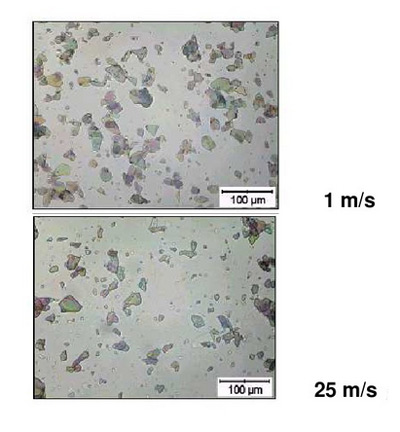

O estado laminar e a consequente fragilidade (quebra fácil) do pigmento exigem o uso de forças de cisalhamento muito baixas durante a dispersão. Máquinas utilizadas para misturar pigmentos comuns, como moinhos de rolos, moinhos de bolas ou moinhos de pedra, não devem ser usadas, pois podem danificar a lâmina. A estrutura semelhante à dos pigmentos causa perda de brilho. Se for utilizado um dispersante, o tempo de mistura permitido deve ser curto. Recomenda-se utilizar tempos e velocidades de mistura iguais para cada lote de tinta, sob condições idênticas.

Perguntas frequentes

Q1: O que é o método de dispersão de pigmentos perolados?

A quantidade de pigmento utilizada deve ser inferior a 25%. A agitação em baixa velocidade é fundamental.

Pré-umedeça o pigmento.

Após umedecer completamente, despeje gradualmente o pigmento perolado restante.

Após umedecer completamente, continue mexendo por 15 minutos.

Q2:

Você pode fornecer orientações online sobre como dispersar corretamente os pigmentos perolados?

Sim.

Pigmento perolado iSuoChem

A Ltd. conta com engenheiros profissionais que podem se comunicar com você online e fornecer orientações sobre como dispersar corretamente os pigmentos perolados, incluindo sugestões de formulação.

A iSuoChem é uma das maiores exportadoras de pigmentos e pastas peroladas da China. Exporta mais de mil toneladas anualmente, principalmente para mercados internacionais. Você pode enviar um e-mail para [email protected] a qualquer momento para obter formulações e diretrizes de fabricação de tintas e revestimentos perolados.

Pigmento de pérola dourada para fazer tinta/pintura perolada dourada

Q3: Como dispersar e estabilizar pigmentos perolados?

Dispersão e estabilização de pigmentos perolados:

Manter a integridade, a molhabilidade completa e o alinhamento paralelo das partículas finas, planas e lamelares de mica.

1. Dispersão (Molhamento e Separação):

O método para dispersar pigmentos perolados de forma eficaz foi detalhado acima. Além disso, lembre-se de usar um dispersante: um agente umectante compatível (surfactante) ajuda a revestir e separar as partículas.

2. Estabilização (Prevenção de Assentamento e Promoção do Alinhamento):

Modificadores reológicos e o uso adequado de aditivos tixotrópicos (por exemplo, sílica fumada para aditivos à base de solventes, espessantes associativos para aditivos à base de água).

Isso evita a sedimentação do pigmento perolado (que se deposita no fundo), garante que as partículas peroladas estejam perfeitamente alinhadas durante a aplicação e as "fixa" no lugar após a aplicação, resultando em um brilho ideal.

Um princípio simples para tintas peroladas: baixa força de cisalhamento durante a mistura, alta viscosidade em repouso.

a equipe profissional para atender !